Introduction:

Pressure gauges are very important tools for checking the pressure of your method. To make certain reliability, it is essential to calibrate your pressure gauge routinely. This short article will go over the best way to appropriately sustain and maintain pressure gauges to make sure exact calibration.

Calibration Basic principles

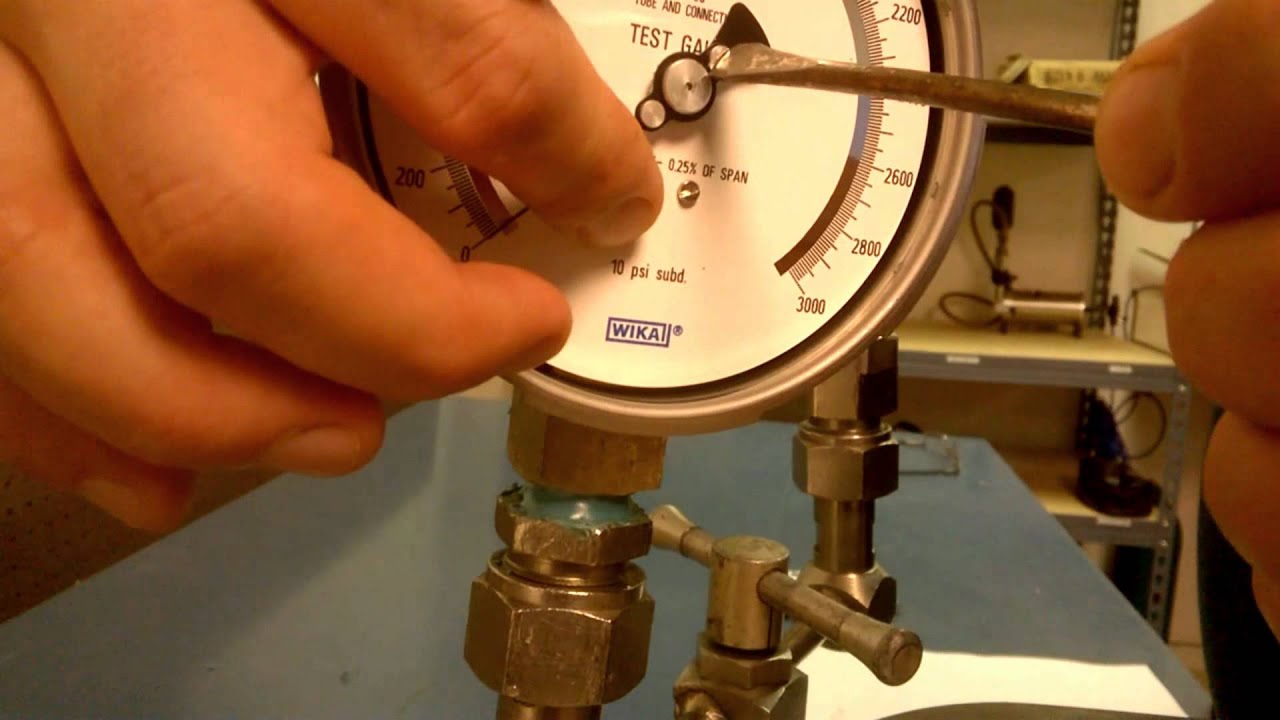

pressure gauge calibration is the method of altering the instrument’s studying to match a known reference point benefit. Calibration helps lessen problems and increase accuracy when measuring pressure, so it is important to make sure your pressure gauge is calibrated correctly. The regularity at which you ought to calibrate your pressure gauge is dependent upon how frequently you make use of it and the way crucial the accuracy is designed for the application. Typically, most producers propose that you calibrate annually or even more frequently as required.

Servicing and Attention Tips

As well as regular calibration, some servicing and attention tips might help keep your pressure gauge precise over time. Here are some stuff to be aware of:

•Keep the temp of the environment the place you shop your pressure gauge constant—ideally between 10-30 degrees Celsius (50-86 qualifications Fahrenheit). Imbalances in temperature may cause inaccurate data.

•Steer clear of tough conditions for example regions with good quantities of dust or severe humidness since these may cause corrosion or corrosion of internal elements, contributing to inaccurate data.

•Ensure that all relationships are restricted and protected to prevent any possible water leaks. Water leaks can cause wrong numbers on account of lack of air flow pressure or pollution from chemical substances and dirt inside the setting.

•Look for any actual physical injury such as dings, cracks, or reduce elements which could impact the accuracy and reliability from the instrument’s looking at. If any problems is found, it must be mended immediately with a skilled specialist prior to the application of the tool resumes.

Verdict:

Precise calibration is vital for guaranteeing appropriate dimensions having a pressure gauge. Standard routine maintenance and care will help make certain accurate measurements over time thus ensuring your system continues to be dependable and harmless for procedure. Trying to keep an eye on environmental conditions like temperature imbalances, humidness ranges, airborne dirt and dust ranges, and so on., and also checking for almost any actual physical damage may help prolong its life span and accuracy and reliability after a while too! All which means that making use of correct maintenance tactics will not likely only boost reliability but also boost performance!